How to choose rubber sheet for engineering mines?

How to choose rubber sheet for engineering mines?

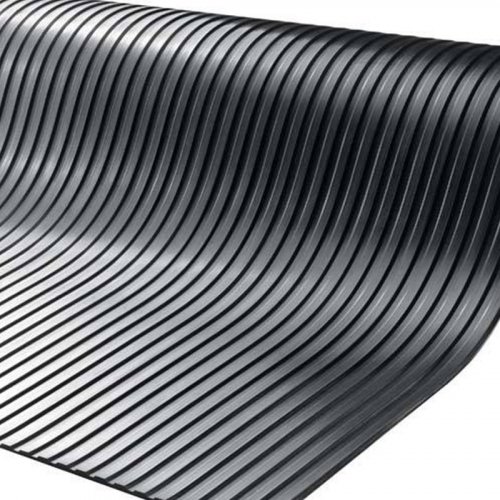

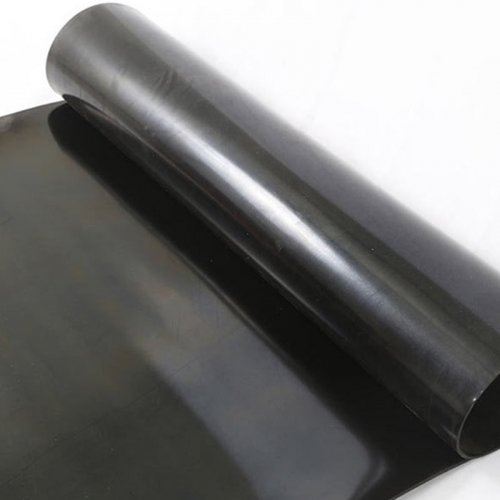

Wear-resistant rubber sheet for engineering mines is a durable material specially used in mines, quarries, construction projects and other fields. It is usually used to protect equipment, reduce wear and extend the service life of equipment. This rubber sheet has good wear resistance, high strength and elasticity, and can resist the impact and friction of hard objects such as ore, sand, and metal.

1. Material characteristics

Strong wear resistance: Wear-resistant rubber sheet is made of natural rubber (NR), styrene-butadiene rubber (SBR), nitrile rubber (NBR), etc. The material has high wear resistance and can effectively resist mechanical impact, wear and erosion.

Good elasticity: The rubber sheet has high elasticity, can absorb impact force, reduce damage to equipment, and help protect the life of the equipment.

Corrosion resistance: Some wear-resistant rubber sheets are specially treated to resist corrosion from chemicals such as acids, alkalis, and oils, and are suitable for harsh working environments.

2. Application areas

Mines and quarries: Used for mining equipment linings, such as conveyor belt linings, chutes, bucket cars, hoppers, etc., which can effectively reduce the wear of ore on equipment.

Construction projects: used as linings for concrete mixing plants to prevent wear on mixing equipment during mixing.

Steel plants and power plants: used as pipeline linings and hopper linings to reduce wear during material transportation and protect pipelines, equipment, etc.

Docks and ports: used in loading and unloading equipment, bulk cargo handling and other scenarios, rubber sheets can effectively reduce wear and impact of materials.

3. Classification

Natural rubber (NR) wear-resistant sheet: has good elasticity and wear resistance, suitable for general industrial use, especially in situations where wear resistance is high.

Styrene-butadiene rubber (SBR) wear-resistant sheet: has good wear and tear resistance, and is usually used in high-wear environments such as mining and conveying equipment.

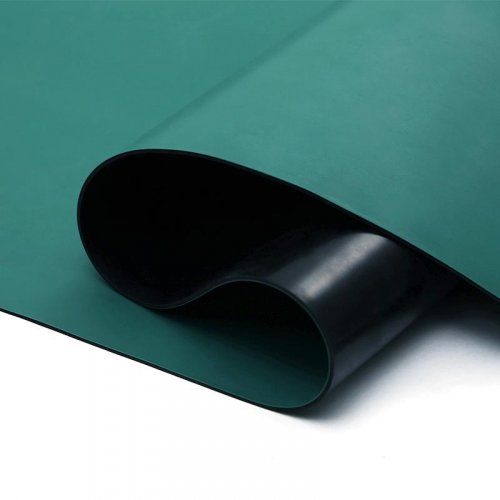

Polyurethane rubber sheet: has excellent wear and tear resistance, suitable for extremely high-wear application environments such as ore transportation.

Nitrile rubber (NBR) wear-resistant sheet: on the basis of wear resistance, it has good oil resistance and is suitable for industrial occasions in contact with oil.

4. Advantages

Impact resistance: The high elasticity of the wear-resistant rubber sheet enables it to effectively absorb the impact of materials on equipment, reducing equipment damage and maintenance costs.

Extend equipment life: By installing wear-resistant rubber sheets, the service life of the equipment can be greatly extended, reducing the frequent replacement caused by wear.

Noise reduction effect: The rubber sheet has a sound-absorbing effect, which can reduce the noise generated during the operation of the equipment and improve the working environment.

Easy to install and replace: Wear-resistant rubber sheets are usually flexible, can be easily installed on the equipment, and are easy to replace.

5. Application examples

Mine conveyor belt pads: During the ore transportation process, ore particles are prone to wear on the conveyor belt. By installing wear-resistant rubber sheets, the service life of the conveyor belt can be effectively extended.

Crusher pads: When the ore enters the crusher, due to strong friction and impact, the inner wall of the crusher will be worn. The use of wear-resistant rubber sheets can protect the inner wall from damage.

Chute lining: Used in mining and sand and gravel transportation, by installing wear-resistant rubber sheets in the chute lining, the wear on the chute can be reduced.

6. Selection suggestions

When choosing wear-resistant rubber sheets, it is necessary to select the appropriate type of rubber sheet according to the application environment, material hardness, temperature, acidity and alkalinity, and other factors. For example:

For high wear and strong impact environments, polyurethane or natural rubber wear-resistant plates can be selected.

For occasions that require oil resistance and wear resistance, nitrile rubber wear-resistant plates can be selected.

In environments with large temperature changes, rubber plates with good temperature resistance need to be selected.

Engineering mining wear-resistant rubber plates are an important protective material that can effectively extend the service life of equipment and reduce maintenance costs and downtime. Its high wear resistance and good elasticity make it widely used in mining, construction, metallurgy and other fields, especially in occasions that require high-strength protection. Choosing the right wear-resistant rubber plate is crucial to improving production efficiency and equipment durability.